Your Global Automation Partner

The Best Move: Decentralized Safety Technology

Decentralized safety systems place personal protection close to the danger points.

Ethernet-based safety I/O modules guarantee personal protection directly at the machine module. This enables designers to shorten cycle times and create machines from autonomous units which are easier to expand and can be put into operation faster thanks to stand-alone tests.

High-performance safety-Ethernet communication connects all units. By distributing the safety logic in the field, non-affected applications remain productive even during an emergency stop of adjacent processes.

Webinar - How Decentralized Safety Technology Can Shorten Commissioning Times

Three Versions of Decentralized Personal Safety

For each individual application, the user decides on the extent to which decentralized safety is transferred to the field. By way of example, we can distinguish between three different concepts of decentralized safety.

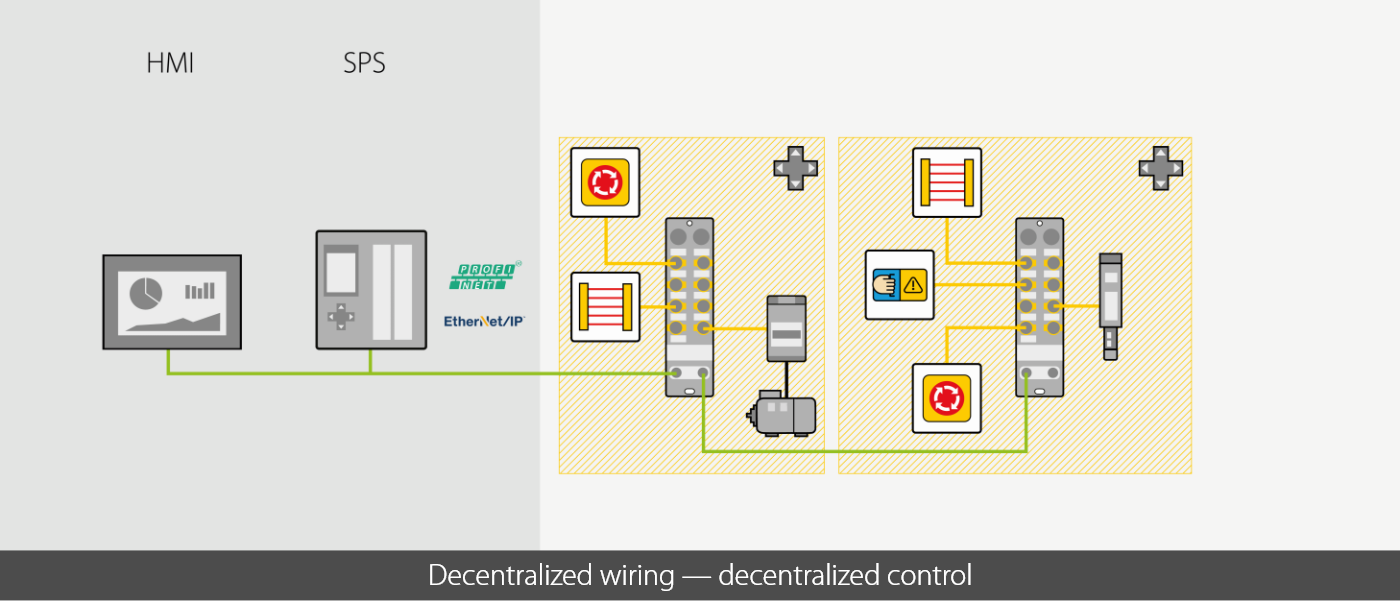

Scenario 1: Decentralized wiring — decentralized control

The safety I/O modules themselves assume control of the application — both in the test run and in live operation. In addition to the safety components, standard sensors/actuators can be connected to the I/O module via I/O-Link ports. Advantages: Complete independence, flexible expansion, minimal mechanical effort and stand-alone tests shorten commissioning times

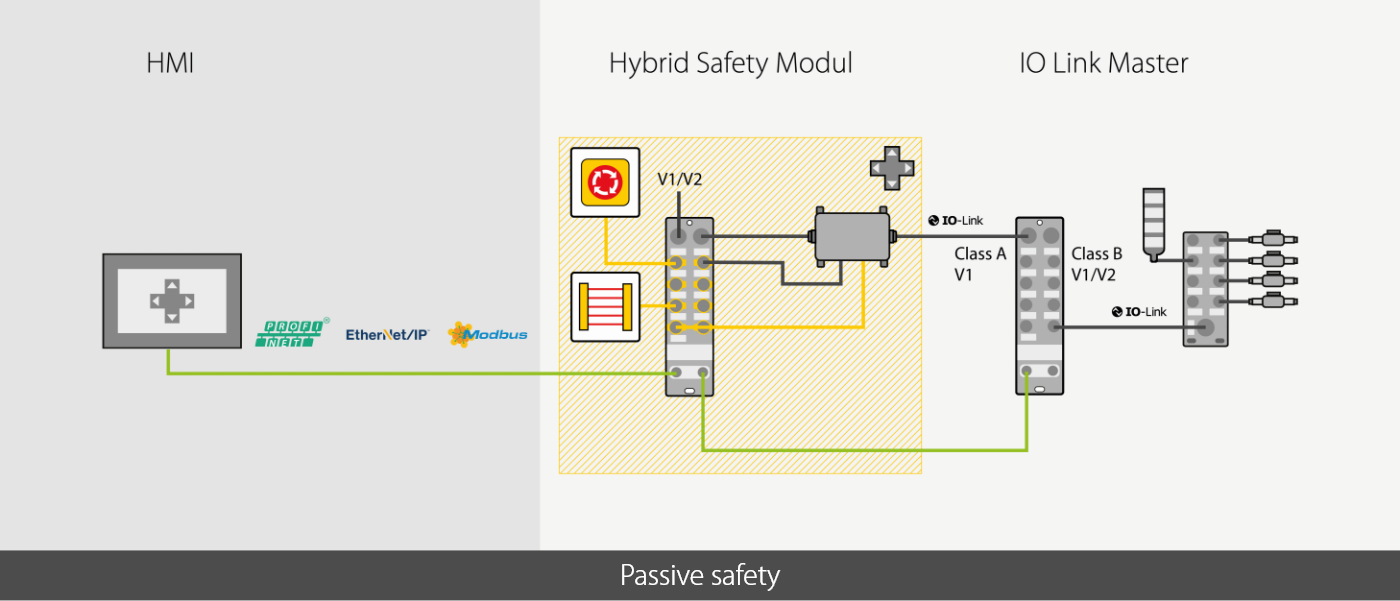

Scenario 2: Passive safety

In this scenario, the safety signals are collected in the field and transferred to the safety PLC via the safety-Ethernet protocols Profinet or CIP Safety. The benefit: Stand-alone tests of the application on the internal controller of the safety modules shorten commissioning times.

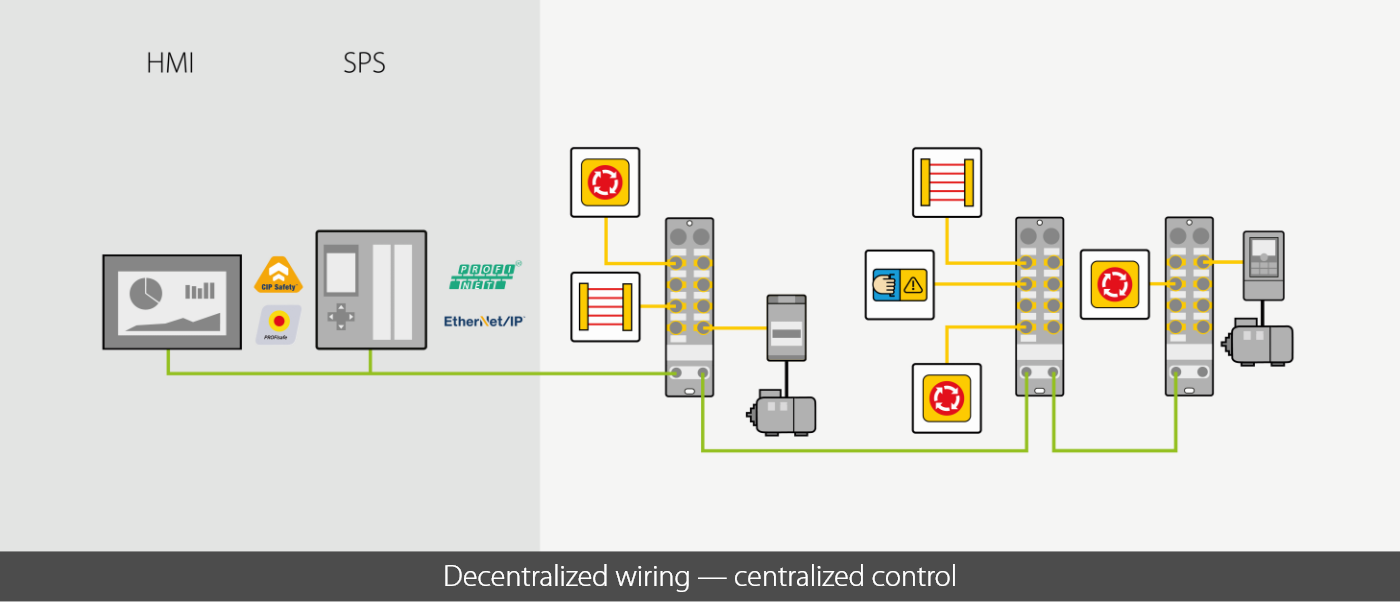

Scenario 3: Decentralized wiring — centralized control

The decentralized concept with passive safety is based on the consistent galvanic isolation between actuator and sensor voltage. In an emergency, the actuator voltage can be safely switched off while the sensor system remains active. Advantages: The minimum number of safety inputs saves costs and diagnostics remains possible despite an emergency stop.

Worldwide use

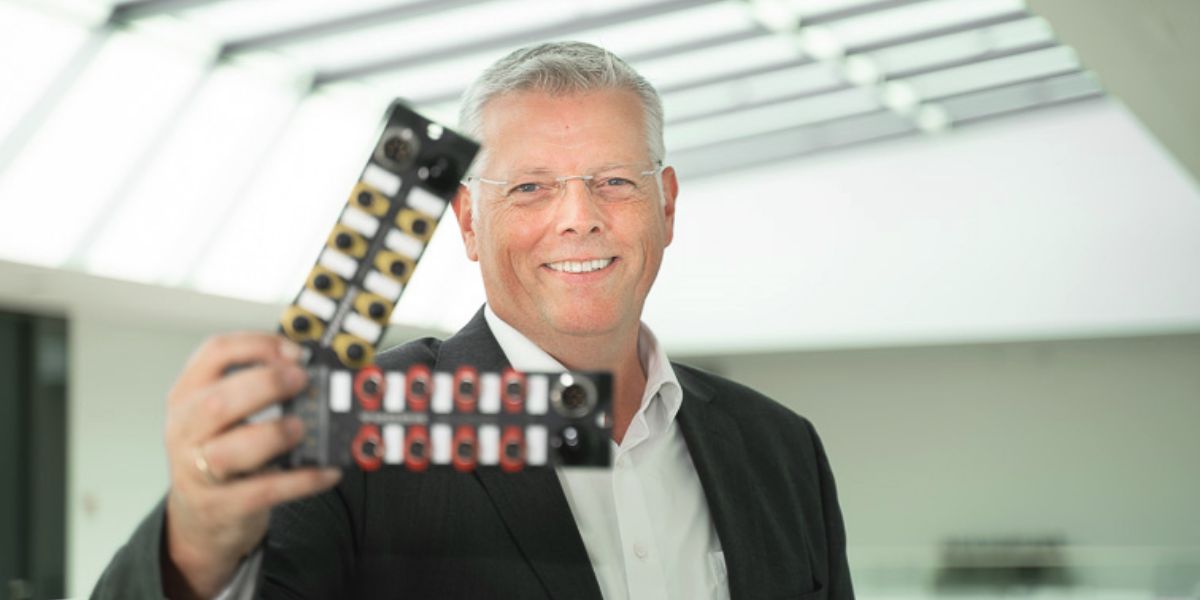

The hybrid and full-safety I/O modules are available as TBPN with Profinet/Profisafe for the European market or as TBIP with Ethernet/IP/CIP Safety for the American market — ideal for export-oriented mechanical engineering.

Copy-and-paste safety

Programs of the Turck Safety Controller can simply be copied to a USB stick directly on the module and copied to other modules with the same tasks — including between devices with Profisafe and CIP Safety.

Decentralized Safety Modules Secure the Palletizing System

Whitepaper: Safe Risk Assessment of Modular Machines

Take the right steps in risk assessment of a linked machine or integrated manufacturing system (IMS). This free whitepaper gives you a practical example of how to identify, describe and reduce potential hazardous situations.

Decentralized Safety in Detail

Full-safety and hybrid module

Turck’s safety hybrid module combines safe inputs/outputs with standard I/Os and IO-Link ports. This allows signal requirements to be mapped flexibly. If more safety signals are generated, the full safety module is used. Both versions—the full and the hybrid module—are available for Profinet/Profisafe or Ethernet/IP/CIP Safety.

Technology page machine safety

Advantages and disadvantages of different safety concepts, as well as technical details about decentralized safety solutions, an overview of all safety technology product groups and examples of successful safety technology applications from Turck can be found on the technology page machine safety.

Functional safety for man and machine

Whether centralized or decentralized solutions for modular machines: Turck's scalable safety portfolio enables customized and flexible solutions for machine safety in any application.

Watch the video to see which application advantages you can realize with the SC10, XS26 safety controllers or the IP67 I/O modules.