Your Global Automation Partner

Optimize Logistics Applications & Reduce Costs

What do reliable delivery times, error-free manufacturing and agile production down to batch size 1 have in common? They all require seamless process transparency based on RFID data.

Outdated processes, complex structures as well as high cost pressure present manufacturing plants and logistics operations with the same challenge: Rapid decision making based on real-time information is becoming increasingly more important in order to stay competitive.

Get more reliable decision-critical information with RFID

RFID systems bridge the gap between the production world and IT-based MES and ERP systems. By linking objects with the data in the IT systems, RFID systems generate the necessary transparency for lean processes and digitalized delivery chains. The aggregated information, such as time, location, users, or completed processes, allow smart functions such as automated production and ordering processes. RFID information enables your systems and decision-makers to make the right choices. You'll increase efficiency and develop resilience against unforeseen events. Turck RFID – ready for intelligent decisions.

Why Turck RFID systems?

Our turnkey RFID solution partner, Turck Vilant Systems, has more than a thousand of installations around the world. Solutions include in-house middleware and ERP integration. Coupled with Turck's many years of experience with RFID for production control, we offer complete solutions, which cover the entire supply and production chain – from the supplier to production to shipment.

Tap Into our Experience in a Every Part of Production and Logistics

Material tracking

- Incoming goods and inventory management automated

- Any changes in inventory levels are recorded and balanced out by automated order processes – the non-availability of an item is impossible

- Efficient warehouse management and production planning based on reliable material inventory data in ERP and warehouse management systems (WMS)

Production tracking

- Correct production conditions and quality as well as material flow are monitored and ensured with tool identification at the machine

- Reliable material assignment guarantees high production quality and eliminates rejects

- Production control: production steps are automatically checked and triggered

Warehouse management

- Products, trays, skids, workpiece holders are given a unique ID and thus identified

- Minimized inventory costs and procurement times, transparent information on all storage areas

- End-to-end traceability of routes and location for goods and production

- Transparent tracking order picking and shipment processes

Picking & shipping

- Robots or utility vehicles fitted with RFID pick items automatically

- The digital order picking list checks the contact of each shipment

- Fewer complaints arising from incorrectly prepared or shipped deliveries

- Improved utilization of logistics units as well as optimized route planning thanks to reliable database

Making Objects Smart

RFID links physical objects with data sets and IT systems. Regardless of the type of object you wish to link to your individual system landscape – we can make the connection.

Key technology for digitalization

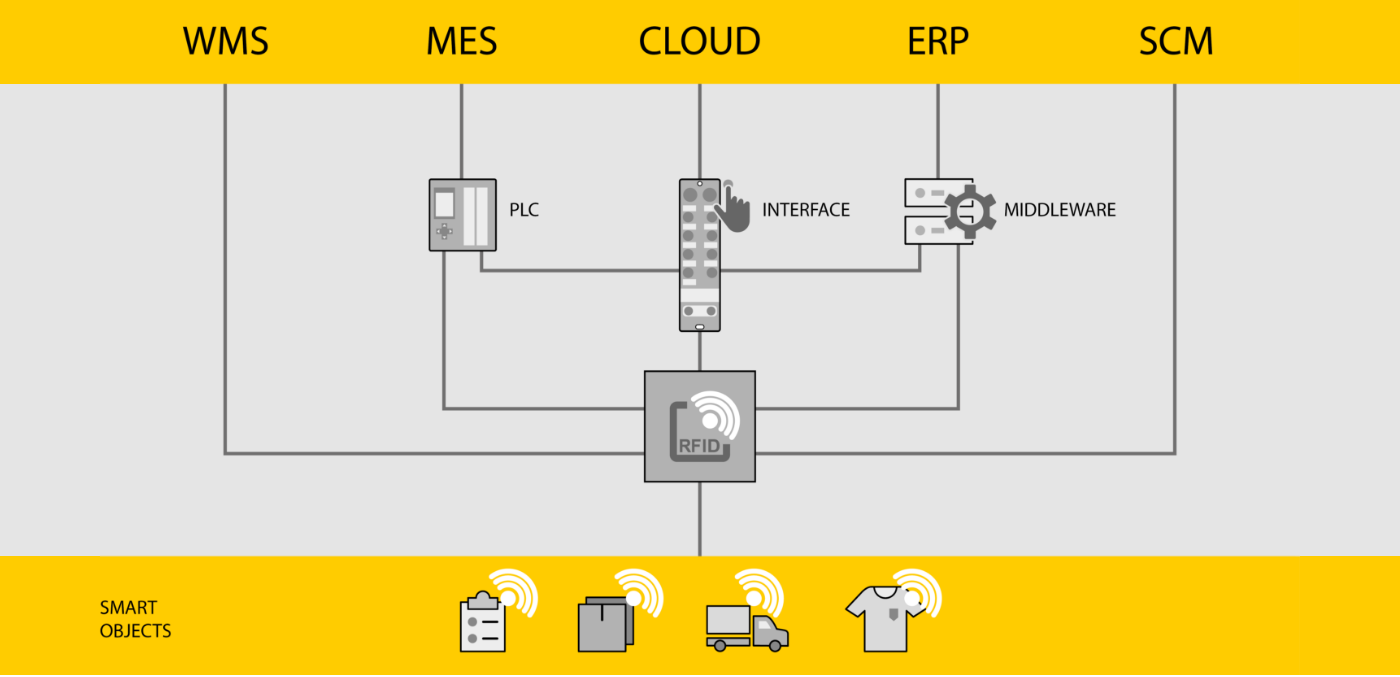

The key requirement for IIoT, the Industrial Internet of Things, is the use of smart industrial components that enable physical objects in production logistics to be present on the Internet. Regardless of whether it is a container with raw materials, components, primary products or finished products – all components can communicate with each other as smart objects in the network when fitted with RFID tags. This turns RFID into a key technology for IIoT.

Information generation

The information of each smart object is captured via strategically positioned read points. Depending on the application, this information is sent via an interface directly to higher-level systems such as an ERP, PLC or Turck Vilant middleware. As a result, Turck's system solutions bring the object data to the level of company applications and factory automation systems.

What are the Benefits of RFID?

More efficient processes

- Avoid time-consuming manual work steps or reduce manual errors

- End-to-end identification and tracking of goods flow and object movement

- Bulk-reading | Detect several objects at the same time

Improved quality control

- Eliminate errors, for instance during tool change or material feed

- Full visibility and transparency through the complete supply chain

- Tamper protection via individual coding

Future-proof investment

- Complete system solution from Turck, expandable everytime needed

- All RFID equipment and complete data handling is based on global standards

- Combination of HF / UHF RFID for complex or new requirements

Whitepaper: Managing RTIs in Real-Time

Which technical solution guarantees efficient tracking of reusable containers? What are the benefits of RFID compared to other information technologies? Which tag is best suited to your application? Our white paper gives you the answers.

RFID Tracking in Practice

Look at the application examples to see how users benefit from RFID in production logistics – with practical and instructive examples.