Modular Plant for Flexible and Efficient Production

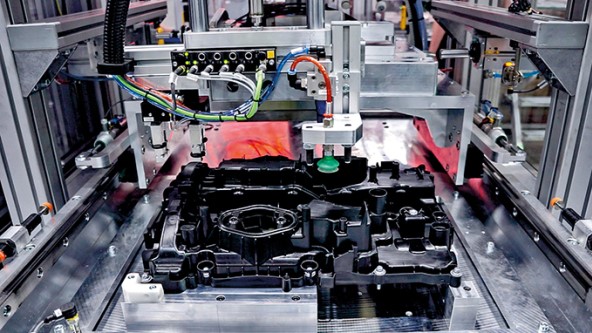

Smart Automation developed a modular production line with decentralized control for an automotive supplier – from sensors to multiprotocol I/O modules, pre-assembled connection technology, LED lights right through to RFID

Polish system integrators Smart Automation developed and implemented a new production line for valve covers for a tier-1 automotive supplier. The modular concept of the production line and the decentralized control was able to meet all the customer’s requirements. Components from the Turck portfolio, which boasted a host of features including Ethernet multiprotocol functionality and the ARGEE decentralized onboard logic, provided the flexibility and reliability of the dynamic line.

Modern production plants for industry require increasingly more flexible solutions. Whether it’s changing production volumes, dynamic demands placed on the shape and size of the parts to be produced, and the need for rapid changeovers for new products, manufacturers in many industries are faced with the task of efficiently mastering the new challenges.

Smart Automation developed a production line for valve covers for a tier 1 automotive supplier, based on modular machines and decentralized control. This modular concept enables more flexible and efficient production, allowing a faster response to changing market conditions and customer needs.

Modularity on multiple levels

The line combines modules for numerous tasks, including the UV laser printing of data matrix codes for traceability, induction heating, assembly and measurement of aluminum inserts, and robot-based deionization and surface cleaning for rubber sealing. Numerous measurements and leak tests also had to be carried out, from diameter and roundness to leakage, flow and pressure drop tests. Each workstation consists of three submodules for transport, process and construction. With the modular structure of the workstations, Smart Automation was able to achieve standardization at the design, assembly and programming levels, which greatly simplifies any changes that may be necessary later in the life cycle of the machine.

Future-proof thanks to standardized device integration

A key requirement for the production line was the use of different Ethernet protocols. With their Ethernet multiprotocol functionality, Turck’s BL67 and TBEN series I/O modules were therefore the ideal solution for this project. They combine the three Ethernet protocols Modbus TCP, Ethernet/IP and Profinet in a single device and can be run automatically in any of the three networks. This enabled the number of device variants required to be effectively reduced.

The Turck I/O modules used in the line also support the decentralized control approach with their ARGEE onboard logic. This field logic controller functionality can handle small to medium control tasks without placing any burden on the central controller.

Flexible process monitoring with RFID

To fully monitor the manufacturing process, Smart Automation has implemented an RFID-based tracking system in which Turck’s TBEN-S module and HF read/write devices play a central role. All parameters and measured values of the manufacturing process are recorded for each individual part and stored in a database on a server and in the cloud.

Factor 1 sensors with maximum switching distance for all metals

The company chose Turck’s uprox series for the inductive sensors required. As factor 1 sensors, the uprox devices detect all metals reliably and with the same switching distance, thus standardizing sensor selection – another benefit in machine design.

Fast and error-proof: pre-assembled cables

Another challenge with the complexity of this line was the connection technology. But Smart Automation has also found a solution for this in Turck’s extensive connectivity portfolio. Pre-assembled cables of various lengths were selected during the planning phase and passive hubs were used where necessary.

Further Information

- Automotive

- Inductive Couplers Ensure Precise Material Feed

- Body Detection in Automobile Production

- Reliable Skid Detection in Automotive Production

- Error-free JIS Order Picking for Bumpers

- RFID Bus Mode Ensures Quality of Lithium-Ion Batteries

- Level Measurement in Dip Coating Line

- Level Control in Central Lubrication System

- Quality Assurance on the Gluing Robot

- Tilt angle sensor accelerates platform alignment

- IP67 Hybrid Module Processes Safety Signals

- Decentralized monitoring of cooling stations

- Robot welding cells networked with Ethernet

- Monitoring the cooling circuit on welding clamps

- Flow monitoring in drum washers

- Press Shop

- Body Shop

- Paint Shop

- Final Assembly

- Powertrain

- Item-level Detection with UHF RFID

- Supply of cooling lubricant in machine tools

- Controlling hydraulic pressure in pressing plants

- Measuring process pressure on scissor lifts

- Success Stories - Automotive

- Modular Plant for Flexible and Efficient Production

- Decentralized Safety Technology for Modular Production

- Modular Conveyor System

- RFID and I/O modules for Safe Tool Changes

- Muffler Production Wired with IO-Link Junction Boxes

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- RFID Traceability

- RFID in Engine Production

- Bumper Production with Identification

- Solutions for Paint Shops

- Welding and Assembly Sensors

- Angle Sensors for Assembly Systems

- Tool Identification

- Unique Products on the Conveyor Belt

- RFID in the Body Shop

- IO-Link Eases Differential Gear Production

- Chemical

- excom I/O System Enables Safe Hydrogen Liquefaction

- Decentralized Automation in Ex Areas

- RFID Control of Tube Connections in the Ex Area

- Ethernet Signal Connection in the I&C Room

- Ethernet-based Automation of Modular Skids

- Ex Isolation in Modular Process Plants

- Detection of Pigs

- Remote Signal I/O

- Easy Connection of Field Devices

- Signal Processing with System I/O in the Control Cabinet

- Signal Separation with Interface Technology in the Control Cabinet

- Identification of Hose Connections

- Efficient Monitoring of Cabinets in the Field

- Monitoring of Quarter Turn Actuators

- Planning and Assembly of System Solutions

- Success Stories

- Efficient Cooling of Industrial Furnaces with Turck's FS+ Flow Sensors

- I/O System Excom Creates Space in the I&C Rooms

- Zone 2 and 22 RFID

- Efficient Testing Control

- Intrinsically Safe Field Communication

- Process Control System Partnership

- Hazardous Area Remote I/O

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Correct Positioning with RFID in Carbid Production

- Fast conversion in restricted space

- Energy

- Food and Beverage

- Dough Thickness Control in Rolling Machines

- Identification of Food Containers

- Detection of Valve Position

- Detection of Pipe Elbows

- Identification of Chocolate Molds

- Success Stories

- Cloud-based Maintenance for Steam Generators

- RFID Support Enables Track and Trace in Food Production

- Grist for the Mill

- Decentralized Control Modules in Cold Storage

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate Production

- Distributed I/O for Food Equipment

- Remote I/O for Distilleries

- RFID and Autoclaves

- Transparency in Chocolate Manufacturing

- IP67 Power Supplies for Conveyors

- Identification in Food Product Storage

- Logistics

- Preventing Package Jams in the Logistics Center

- Tracking Big Bags with RFID

- Access Control for Protected Areas

- Decentralized Muting of Electro-sensitive Protectice Equipment

- Fast Tag Detection at Warehouse Gates

- Preventive Maintenance on Conveyor Belts

- Detection of Transport Containers

- Level Detection in Vessels

- Identification of Cryovessels

- Identification of Mobile Containers with Handheld Devices

- Identification of Food Containers

- Tier 1 – Bumper Identification

- Collision Protection on Reach Stackers

- Success Stories

- Logistics: RFID Reduces Error Quota by 99 Percent

- Sustainable Tracking of RTIs thanks to RFID

- RFID with HF Bus Mode Eases Seed Storage

- RFID Enables Unmanned Store at Major Building Site

- I/O and Safety Modules Increase Throughput in Intralogistics

- Shipment Tracking for Raw Materials

- RFID-based Shipment Control Minimizes Errors

- RFID-based Tracking of Inbound and Outbound Materials

- Decentralized UHF RFID Solution

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- IP67 Power Supplies for Conveyors

- Modular Conveyor System

- RFID Solution for Warehouse

- RFID Identifies Pharmaceuticals

- UHF RFID in Food Distribution Center

- Mobile Equipment

- Condition Monitoring Sensor Automates Climate Control

- Automatic Slope Compensation

- Distribution Lines for Field Sprayers

- Angle Measurement on a Field Sprayer

- Determining the Boom Angle Position

- Two-Axis Tilt Measurement on a Combine Harvester

- Collision Protection on Reach Stackers

- Success Stories

- RFID Solution with Smart Forklifts in Automobile Production

- Safe Remote Maintenance of Irrigation and Drainage Pumps

- Access Control with RFID System

- Selective Asparagus Harvester

- Position Measurement with RFID and Encoder

- Block I/O Modules on Super Yacht

- Wear-free encoder on hopper dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Critical Angle Sensing

- Angle Indicator

- Oil and Gas

- Packaging

- Decentralized RFID Package Verification

- Identification of Printing Color Cartridges

- Reliable Operation of Machines

- Monitoring of Caps in Filling Lines

- Monitoring Changeover Processes

- Identification of Test Bottles

- Level Monitoring of Ground Coffee

- Level Detection in Vessels

- Detection of Transport Containers

- Success Stories

- Pharmaceutical

- End-to-End Sample Tracking with RFID

- RFID Control of Tube Connections in the Ex Area

- Decentralized Package Verification

- Automate Modular Skids

- Ex Isolation in Modular Process Plants

- Control of Valve Interfaces

- Monitoring of Quarter Turn Actuators

- Detection of Pipe Elbows

- Easy Connection of Field Devices

- Identification of Cryovessels

- Identification of Mobile Containers

- Identification of Mobile Containers with Handheld Devices

- Identification of Hose Connections for Precursors

- Identification of Hose Connections in Sterile Areas

- Identification of Big Bags and Bioreactors

- Identification of Single-Use Applications

- Success Stories

Select Country

Turck worldwide

-turck-image.jpg)

-turck-thumbnail.jpg)