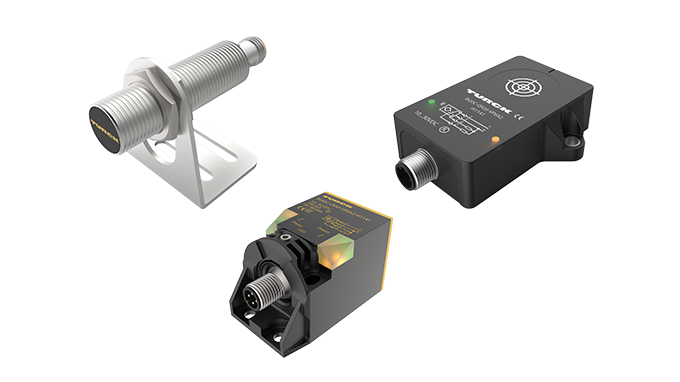

New Sensor Detects both Carbon Fibers & Pressed Carbon Parts

MINNEAPOLIS, MN (September, 2021) – Turck has launched a new line of inductive sensors specifically created to detect carbon fiber materials and pressed carbon parts. These sensors are patent-pending and are ideal for use in the automotive industry. Carbon fibers are being used in production of vehicle’s interiors and body shells, for example. They are less susceptible to contamination than optical or capacitive sensors while also being significantly more economical than ultrasonic sensors.

With high reliability thanks to its Turck Uprox-based technology and wide temperature range of 0-100° C, these IP68-rated sensors are ideal for use in automotive manufacturing as well as alternative energy and sporting goods manufacturing. Available in three designs: M18 threaded-barrel sensor in stainless steel housing and CK40 and QR20 rectangular sensors in plastic housing.

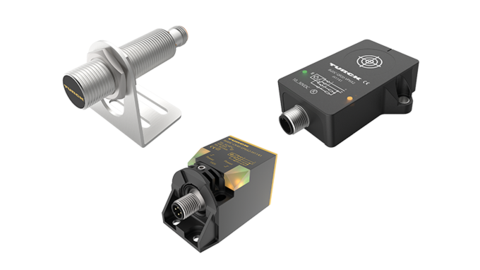

MINNEAPOLIS, MN (September, 2021) – Turck has launched a new line of inductive sensors specifically created to detect carbon fiber materials and pressed carbon parts. These sensors are patent-pending and are ideal for use in the automotive industry. Carbon fibers are being used in production of vehicle’s interiors and body shells, for example. They are less susceptible to contamination than optical or capacitive sensors while also being significantly more economical than ultrasonic sensors.

With high reliability thanks to its Turck Uprox-based technology and wide temperature range of 0-100° C, these IP68-rated sensors are ideal for use in automotive manufacturing as well as alternative energy and sporting goods manufacturing. Available in three designs: M18 threaded-barrel sensor in stainless steel housing and CK40 and QR20 rectangular sensors in plastic housing.

Select Country

Turck worldwide