Turck Introduces Automated Weld Water Detection System

Improve weld water control and weld system protection via IO-Link

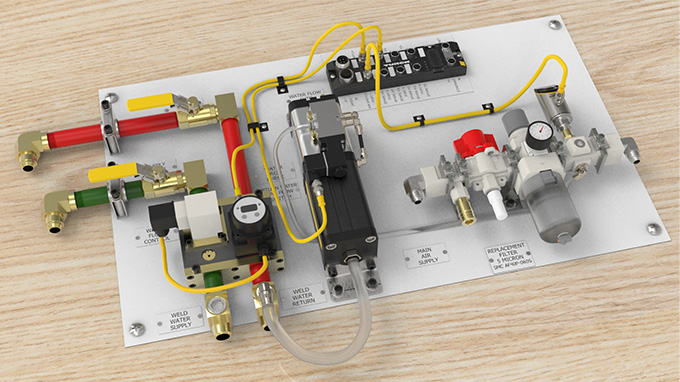

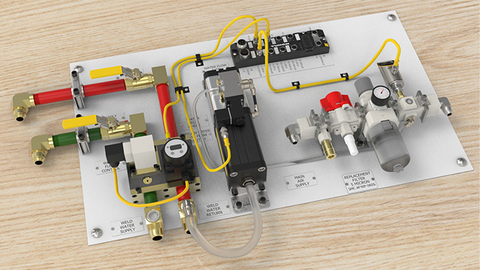

MINNEAPOLIS, MN - Turck has launched a new weld water detection system that helps protect the critical cooling processes during robotic spot welding applications. Preventing welding systems from overheating ensures less damage to machines and reduces downtime and maintenance.

This automated solution is ideal for robotic spot welding systems in machine tools, automotive and Tier 1 welding applications. Communication via IO-Link offers improved monitoring and control due to its ability to track and monitor operations remotely.

The system features rugged components designed for the harsh environments found in welding applications. An auto water shut-off with retract unit prevents excessive water spillage during weld tip change. In addition, manual flow adjustment ensures easy setup and commissioning.

- Helps prevent welder from overheating

- Uses IO-Link to provide fast, remote monitoring of the station via Ethernet

- Provides protection from overheating

- Several pre-engineered variants available

About Turck

Turck is a pioneer in automation technology, providing customers with a comprehensive line of quality and advanced technology products in a fast, flexible and accurate manner. With more than 4,800 people working in 30 countries, Turck has built global partnerships with customers based on engineering expertise, flexibility, and our willingness to take on engineering challenges that others will not.

Select Country

Turck worldwide